March 18th, 2014 So today right on schedule most of the second floor wall has been finished. The front shade is also framed. However, AMX Steel is no show and so the steel beam is not yet welded in place. But at least it is not impacting the framing. Tomorrow is a raining day so no work will be done on site.

At the end of the day, this is what the north and east side wall looks like from the outside.

Continue reading ‘Framing day 9’ »

March 17th, 2014 Framing day 8. Today the crew worked on the second floor wall. They have finished the east wall and 2 panel of walls to the north and 1 panel of wall to the south. Tomorrow they will continue to work on the walls and the front shade. The west side wall will be the last to get done because that’s where they use their forklift to bring in the material.

This is the wall to the north that was finished. You can also see a part of my wall to the east that will contain a sliding door and a large window.

Continue reading ‘Framing day 8’ »

March 14th, 2014 Today is day 7 of framing. After that big snow storm, a lot of clean up has to be done before the work can begin. At least I already cleaned up inside the house. So the crew will only have to do some clean up outside of the house.. The framer worked on framing the balcony today. Here’s the finished product. you can see the extensive use of web fillers to stiffen the joists on every joist. The steel frame wasn’t that level on the balcony, but the framer addressed it and leveled the joists. The floor of the balcony is slanted 1″ back to front for drainage.

Continue reading ‘Framing day 7’ »

March 13th, 2014 Yesterday a snow storm hit Toronto and left us with 15cm of snow. My back yard is instantly transformed.

Continue reading ‘Snow day’ »

March 11th, 2014 Framing day 6. Tomorrow the weather forecast calls for 10-15cm of snow. So the framing crew worked long to finish up the second sub-floor so that the snow won’t be coming in to the unfinished house. Well the snow will still be blown in from the window and door opening but at least the top is mostly covered by the plywood now.

Continue reading ‘Framing day 6’ »

March 10th, 2014 Framing Day 5. There’s only two crew member working today and one of them is not so experienced. So the progress is slow. Part of second floor’s joist is done in the east part of the house. And that’s pretty much it.

Continue reading ‘Framing day 5’ »

March 9th, 2014 Because of the structural steel, our exterior wall needs to be at least 8.5″ thick to hide all the steel beams. I have done some research on wall constructions to see how to construct that 8.5″ thick wall that will provide the best performance. And we ended up with a design with deep Swedish roots. In this post, I will try to explain why we framed the wall the way we did.

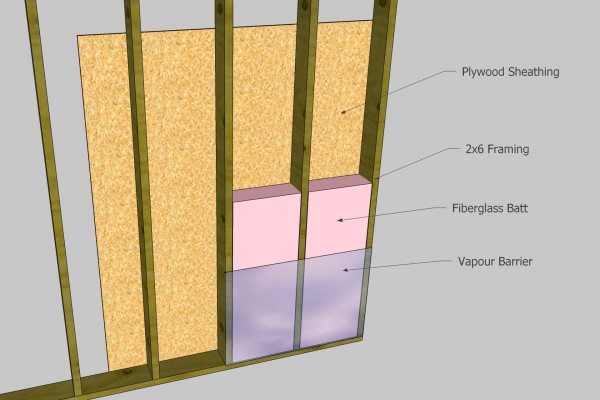

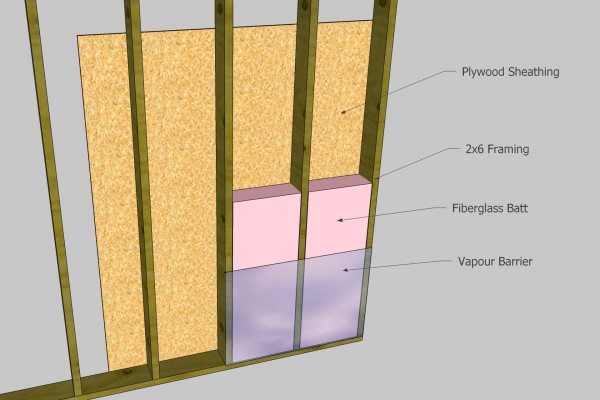

The illustration below is what a traditional stud-framed wall looks like. To satisfy minimum code with the use of fiberglass insulation, the walls are constructed as a 2×6 stud-framed wall. Plywood or more commonly seen now OSB (Oriented strand board) wall sheathing on the outside. The stud cavity is typically filled with figerglass batts which offers about R20. Then 6 mil polyethylene vapour barrier is added to the inside and gypsum drywall to finish up the interior. That’s how a typical wall is constructed today.

Continue reading ‘Exterior wall construction with Swedish roots’ »

March 7th, 2014 Today more deliveries from RONA, dropping off materials for the second sub floor.

Continue reading ‘Framing day 4’ »

March 6th, 2014 Today is framing day 3. The same crew from Pleasant Homes Construction is here working on getting the walls of the first floor.

Here’s how the walls of my house are constructed. As you can see it is a 2×6 stud-framed wall at 16″ on center. However, 2×2 furring are added to the outside of the wall before the 1/2″ plywood sheathing is added. The framer decided to use two 2×4 instead of all 2×2 to secure the plywood sheathing because the 2×2 tends to split easily. But none the less the essence of my wall design is carried out. Once the 2×2 cavity is filled with rigid insulation and the 2×6 cavity is filled with batt insulation, and after interior vapour barrier is installed, another layer of 2×2 furring will be added to the interior, completing my 8.5″ thick stud-framed wall.

Continue reading ‘Framing day 3’ »

March 5th, 2014 Today is the second day of framing. Three crew member from Pleasant Homes Construction is here framing the first sub floor. RONA is also here delivering the material for the first floor walls. Here you see the material that’s delivered to me. My wall is designed very differently from a conventional framed wall that it will be a 2×6 wall with 2×2 strappings both inside and outside. I will write up a separate post on why the wall is designed like so.

Continue reading ‘Framing day 2’ »

|

|